Assignment for week 9 & week 10

- Make a machine

- Including the end effector

- Build the passive parts and operate it manually

- Automate your machine

- Document the group project and your individual contribution

Plotter

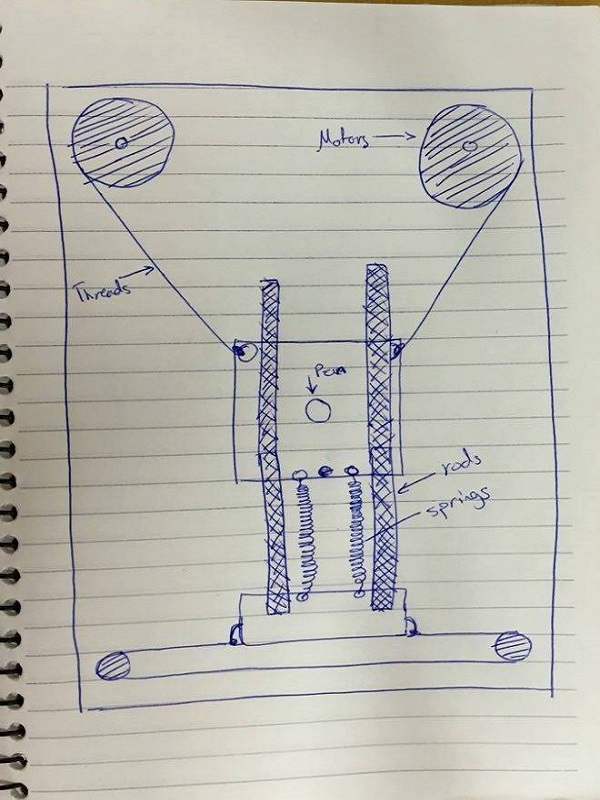

We had a meeting to discuss what we are going to do in the machine design group project. Some ideas were tossed around. we had to choose between a plotter, Foam cutter or a CNC. We settled on fabricating a plotter. Abdullatif suggested that we try a new mechanism. He saw a polygraph displayed at Maker Faire Cairo 2016 and suggested that we modify it a bit. So polygraph uses gravity to pull the pen downwards and two motors are used to direct the pen to the left and right. What Abdullatif suggested was to design a mechanism that do this horizontally and compensate for the gravity using springs attached to a plate that goes right and left on a belt.

Modeling

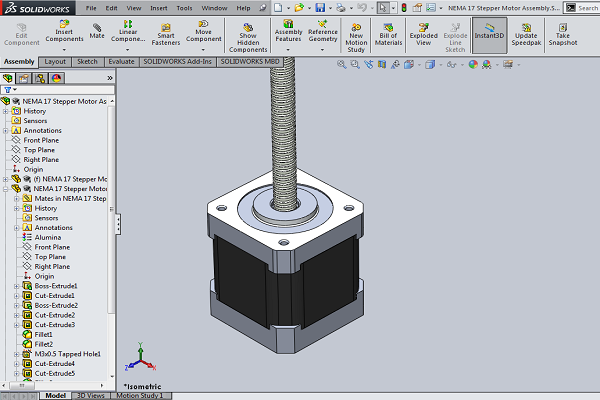

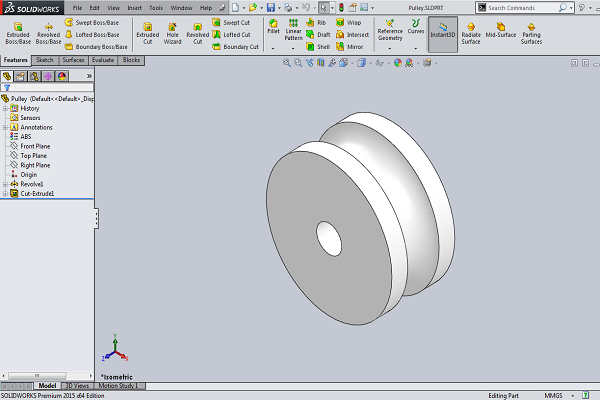

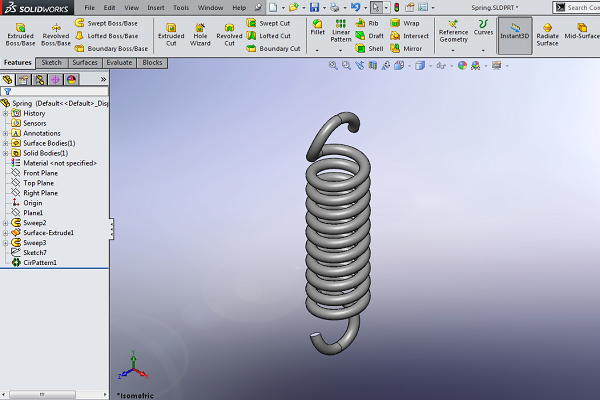

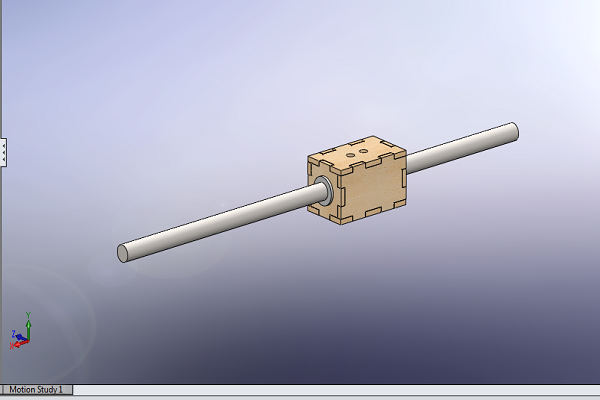

I stared modeling the machine parts using Solidworks.

Motor

Pully

Spring

Slider

Foam Cutter

After a while we decided we would go for something else to we gathered and had a discussion of what the machine would be. We decided that we will make a foam cutter. So we divided the workload into 3 groups:

- Logistics and operations: which was responsible to find the required materials in the local market and work on the assembly of the machine and testing.

- CAD: which was design the machine to be cut in plywood.

- Electronics: which is responsible for understanding the Gestalt system and implementing it.

Logistics and operations

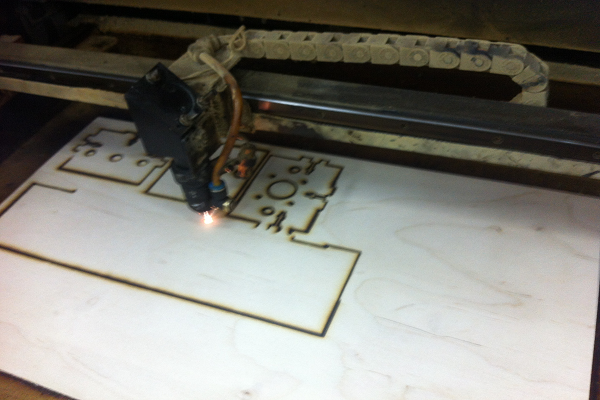

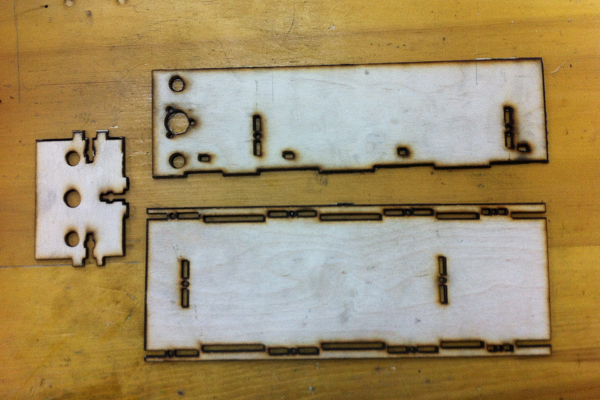

My Main role in this project was in the operation team. I was one of the people handling implementing the desing on laser cutter machine.

The design was made ready by the CAD team, and so we were ON. We used plywood sheet of thickness 3mm for the implementation. Some parts needed to br strong enough to handle weight, so we used 2 sheets and bonded them together to get 6mm.

During cutting, We faced a problem with the laser cutter. There was a problem in the lenses first of all, and then it was fixed. Moreover, because of hot temperature these days in Egypt that reached almost 45 degrees, the laser beam had to be cooled off every almost 30 seconds, so we had to pause and resume till we finished the designs.

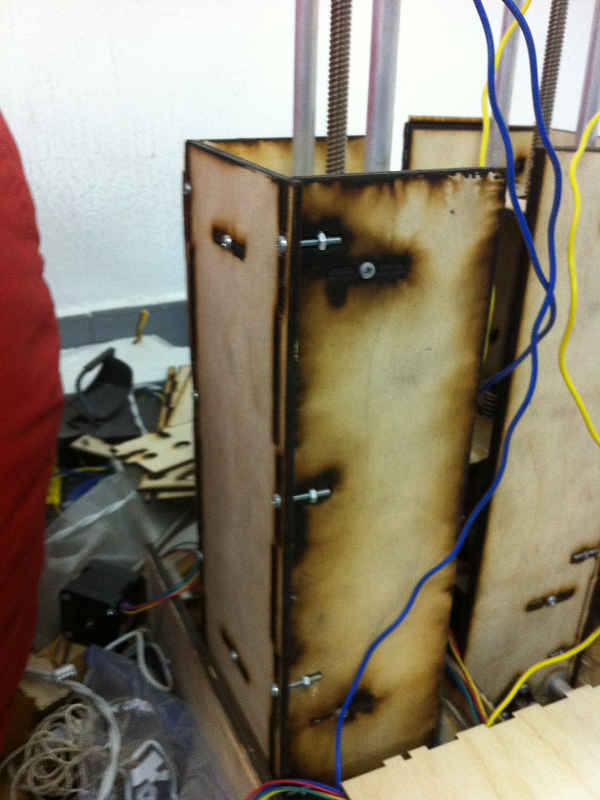

Then assembling with the team.

And here is a video during its testing.

This work by Joseph Gourgy is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.